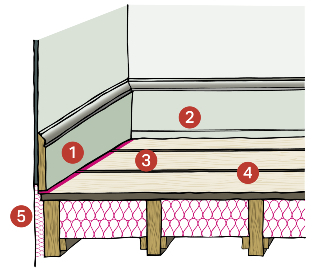

1. Caulking smaller gaps with plaster, decorators filler, or mastic can be an effective way to close air-paths between the interior and a floor void.

2. With larger gaps, where floors have relaxed for example, scribed timber fillets may be necessary to effectively close the joint.

3. Hardboard coverings and underlays beneath carpets can also be effective at reducing draughts.

4. Many timber floors have gaps between the boards through which air can pass, especially those with older plain-edged and butt-jointed boards. Closing these gaps with a compressible caulking strip (preferable as it allows expansion and contraction of the boards) a filler, mastic, or timber slips will help prevent draughts. In severe cases it may even be necessary to lift and relay the boards. Although exposed timber floors are very popular today, it is worth remembering that many were not intended to be on show and their quality of materials and workmanship reflected this.

5. Floor voids and the spaces behind cornices, panelling and the like should be insulated as described elsewhere.

6. Where there are larger gaps, these can be sealed with compacted compressible insulation such as mineral wool or sheeps wool.

Expand the sections below to find out more.

At the edges of a building the places where walls and floors meet afford many opportunities for heat energy to be lost through small gaps.

Cold air can enter the building through 'infiltration' commonly referred to as draughts. Heat can also be lost from the interior through 'exfiltration'.

The arrangement of floor carpentry typically inserts timber joists or wall-plates into the external walls and as these materials behave differently to the masonry, over time cracks and gaps can appear between them.

Air paths are then created through the building fabric. In some older buildings there may also be bonding timbers, lintels, and brackets for features such as panelling and cornices - all of which can introduce further gaps in the building fabric.

Often the masonry of the walls is not as well put together in the smaller spaces between these built-in timbers. Mortars and plasterwork may also be less complete. This means that in the region of a floor, the wall itself may have significantly more gaps than elsewhere on the building.

Internally, room joinery such as panelling, shutters, and skirting boards can become less close fitting over time as the floors and walls of a building move and age. Plaster finishes can also crack and open up behind elements of the building prone to impact such as skirting boards. This opening up of the elements of a building introduces further gaps through which air can pass.

Draughtproofing floorboards with Draughtex. Photograph by Caramel Quin.

The effectiveness of draughtproofing at the perimeter of timber floors will vary from building to building, due to their different arrangement of construction and relative condition or state of repair.

Typically, floor to wall junctions are 5-7% of the building exterior, but uninsulated and draughty construction will contribute proportionately more to the heat loss. Simple upgrade measures here can therefore be remarkably effective.

Draughtproofing timber floors can be very cost effective as the measures normally involve low cost materials that can easily be DIY installed.

Where concealed by joinery, decorative finishes, and carpets the appearance of the measures is less important than their function and this also reduces the cost of installation.

A tube of decorators caulking costs as little as £3!

Listed Building Consent is not normally required, unless the appearance of the room would be significantly affected.

Any mastic-type draught proofing should be as discreet as possible in colour, for example clear, or matching the surrounding colour as closely as possible.

Care should be taken if temporary removal of skirting boards is required.

Sealing the gaps between floorboards, traditionally referred to as caulking, is the most likely of these measures to affect appearance and can make them harder to lift in the future. If you are planning any associated works that may require lifting of floorboards these should be done before sealing these gaps. Proprietary flexible caulking strip is an inexpensive and simple measure for draught proofing the gaps between timber floorboards. It should be noted that comprehensive eradication of natural ventilation beneath timber floors can lead to damp and decay.

Unobtrusive products should always be used.

Loss of historic fabric should be avoided.

Professional installation will be needed for products such as rebated edge seals.

We support careful draughtproofing of floors where there is no detrimental impact on the special architectural or historic interest of the building or historic fabric.

In the light of the Climate Emergency, we will generally permit and encourage alterations on listed buildings, with special regard to the the following:

- Preserving the building, its setting or any features of special architectural or historic interest which it possesses

- Preserving or enhancing the character of a conservation area

- Respecting the significance of any non-designated heritage asset

Draughtproofing Older Buildings also from Historic England